Mastec Ford GT Ute

Posted: Sat Jan 02, 2016 11:38 pm

Mike's new engine build for the black beast.

After setting his new class record in 2014, and finally getting into the 200mph club, suffering gearbox problems throughout the runs, 2014 was a great meeting for Mike, after returning home the gearbox was removed and inspected, completely rebuilt with an added paddle shift system, to help improve shift times, eliminate miss shifts, and keep the car stable throughout the run.

After setting his new class record in 2014, and finally getting into the 200mph club, suffering gearbox problems throughout the runs, 2014 was a great meeting for Mike, after returning home the gearbox was removed and inspected, completely rebuilt with an added paddle shift system, to help improve shift times, eliminate miss shifts, and keep the car stable throughout the run.

2015 speedweek unfortunately didn't go to plan as we would have liked, onboard data showed Mike was travelling 45mph faster at the 1st mile mark than previously in 2014, before the engine decided it didn't want to play the game anymore.

After heading back home whilst the team felt heart broken we were still happy with the progress and the improvement on the car, after removing and inspecting the engine and several months talking, weighing up the pros and cons with what to do with the engine we have decided to get the modular 5.4 moving forward with a new engine program.

Several phone calls and emails to MMR in the states, discussing our best option, we all know building a drag engine is completely different to building an engine for salt lake racing Mike has decided let's push the 5.4 litre v8 to a whole new level, however we are up against a few challenges with the design of the factory engine to with stand the abuse and tortue a salt car engine gets put through.

Sure we can just grout fill the entire block and heads, use aluminum conrods and run methanol, but it's a salt car not a 6 second drag car.

So after many months of drawings, designs, calculations, costings, and sourcing parts we are finally well underway in the engine program to get the Mastec Ute back out on the salt. MMR are supplying a billet crankshaft, custom forged pistons, camshafts and a heap of other parts for the combination, however conrods are a weak point, we have organised a custom set of billet 300m conrods to be machined and all going into a custom billet engine block.

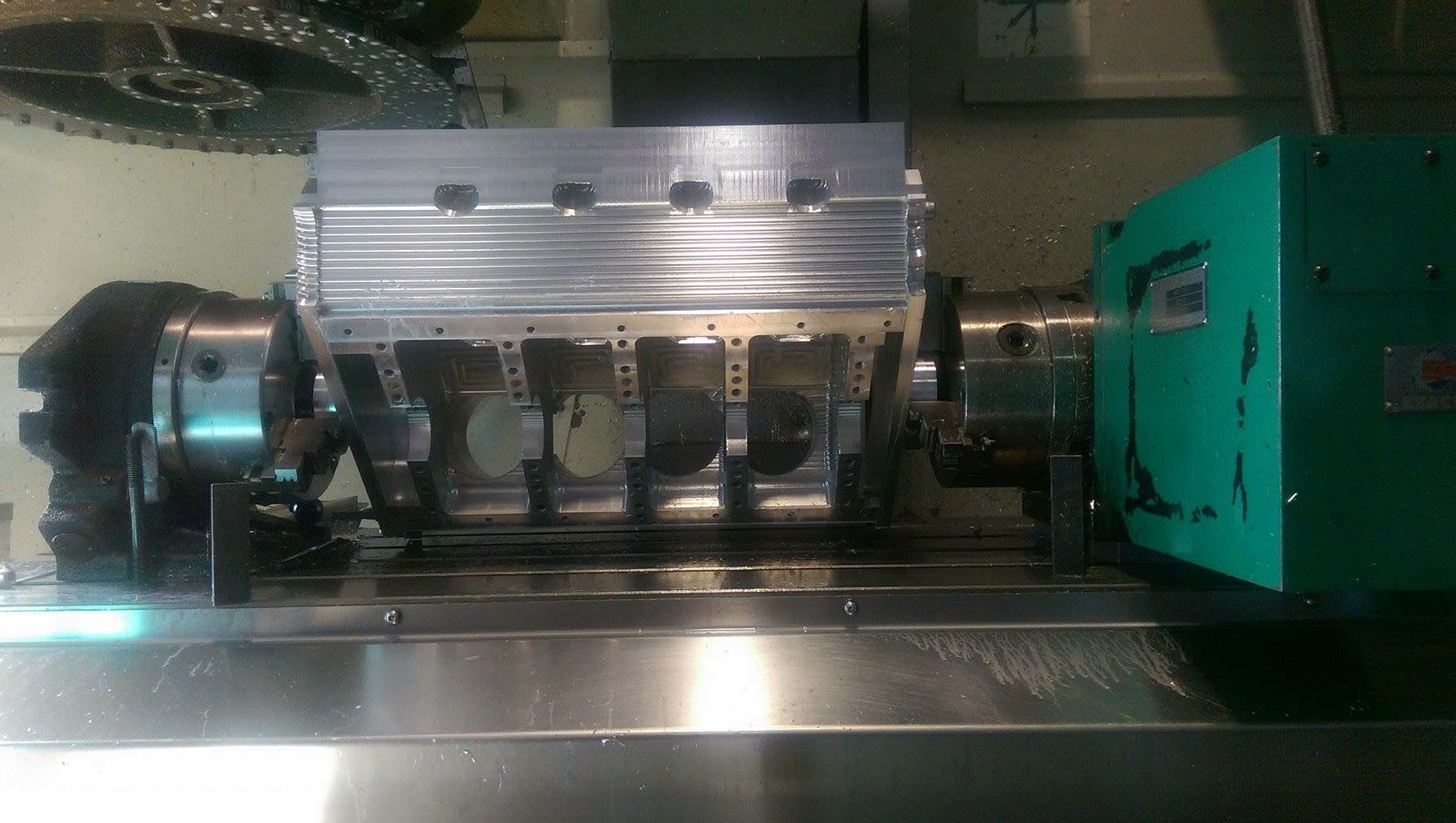

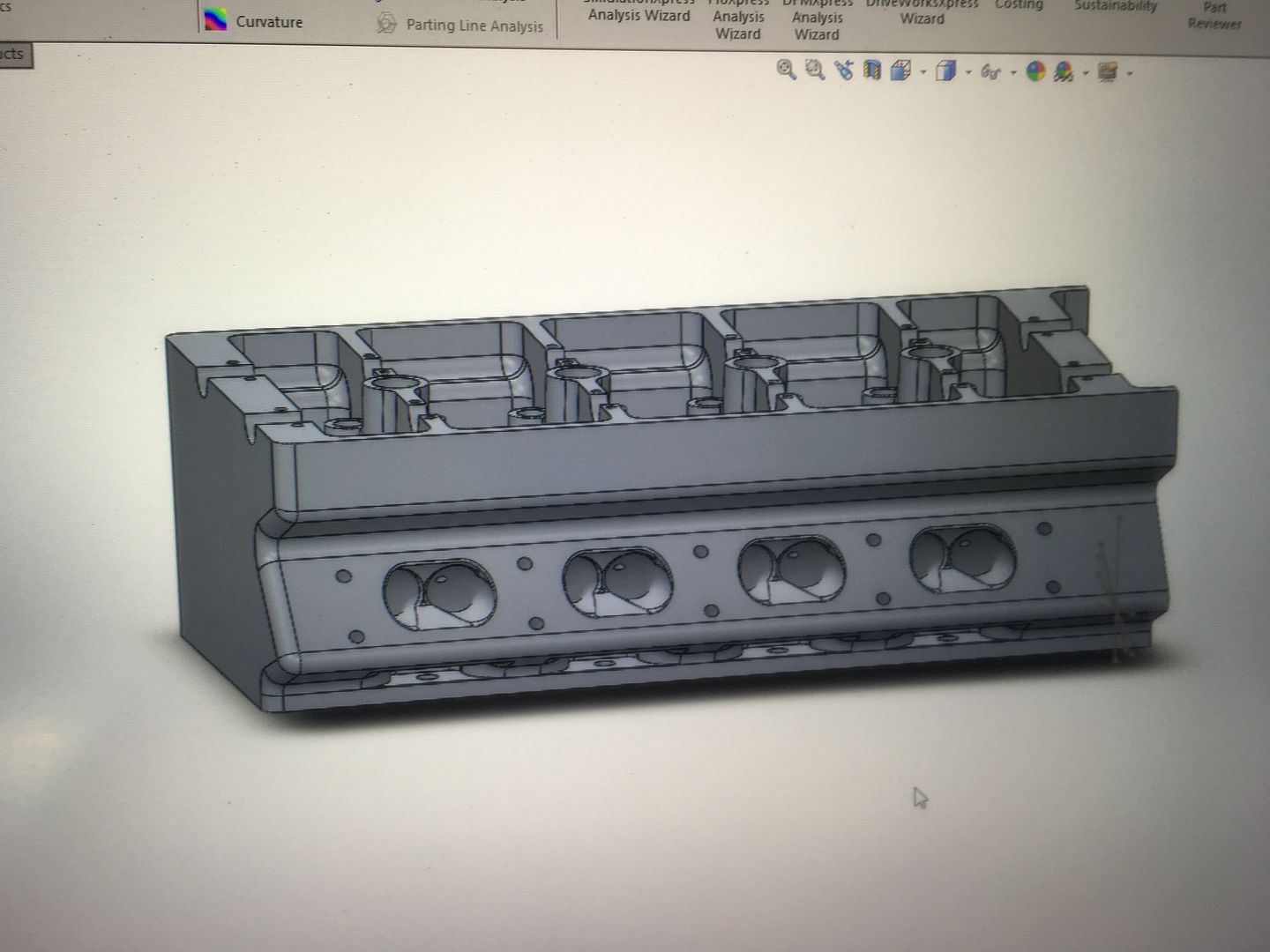

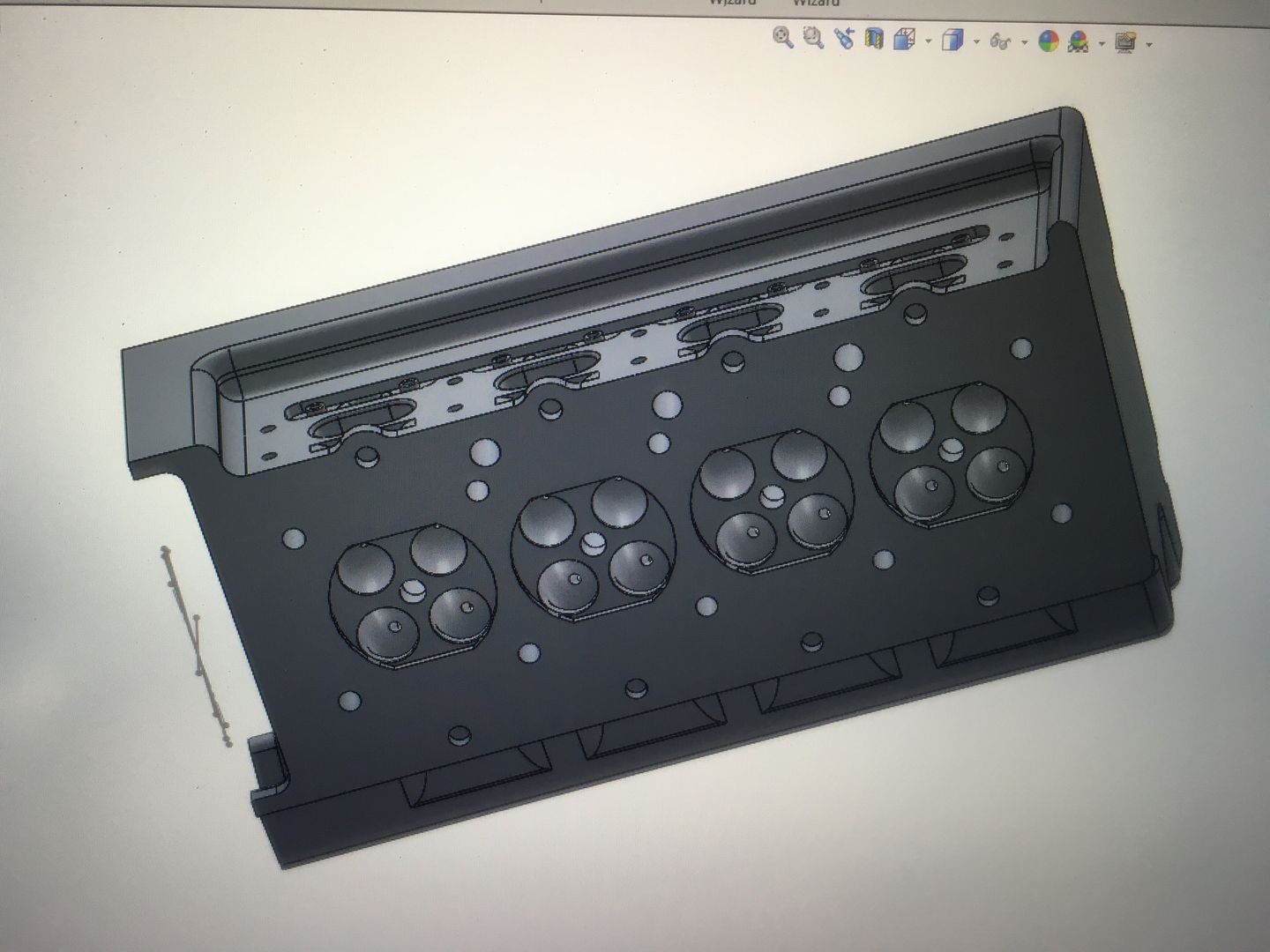

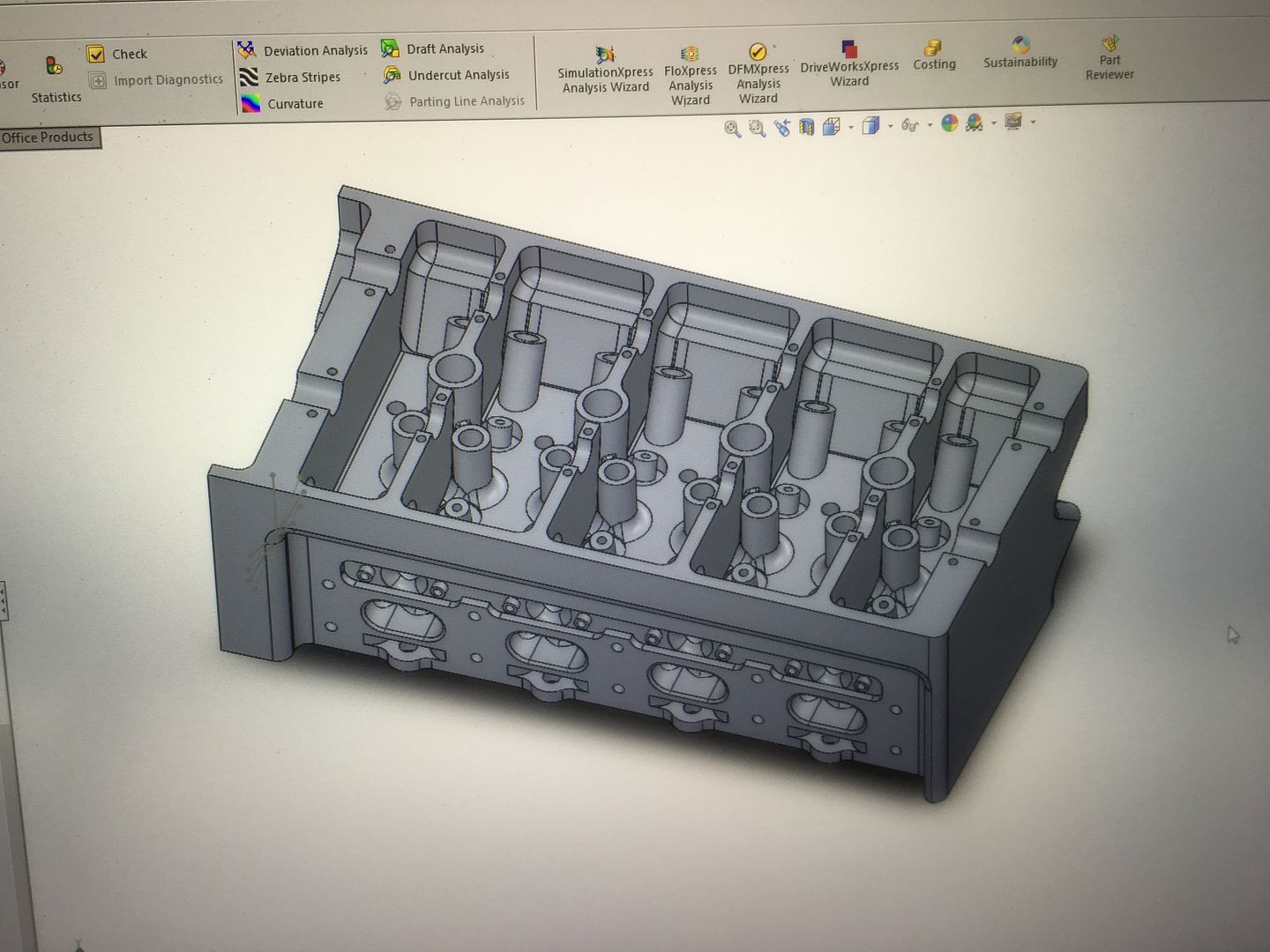

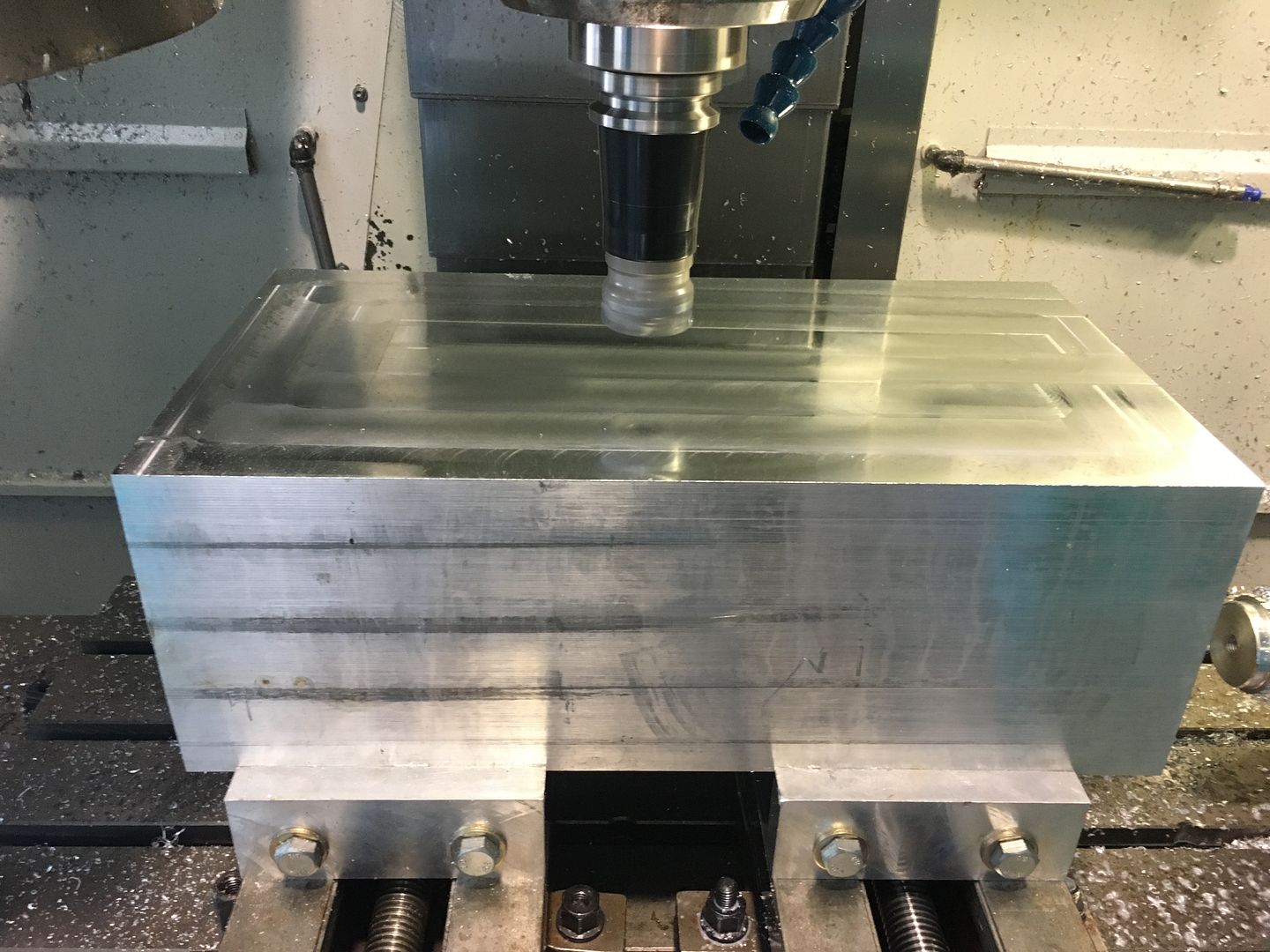

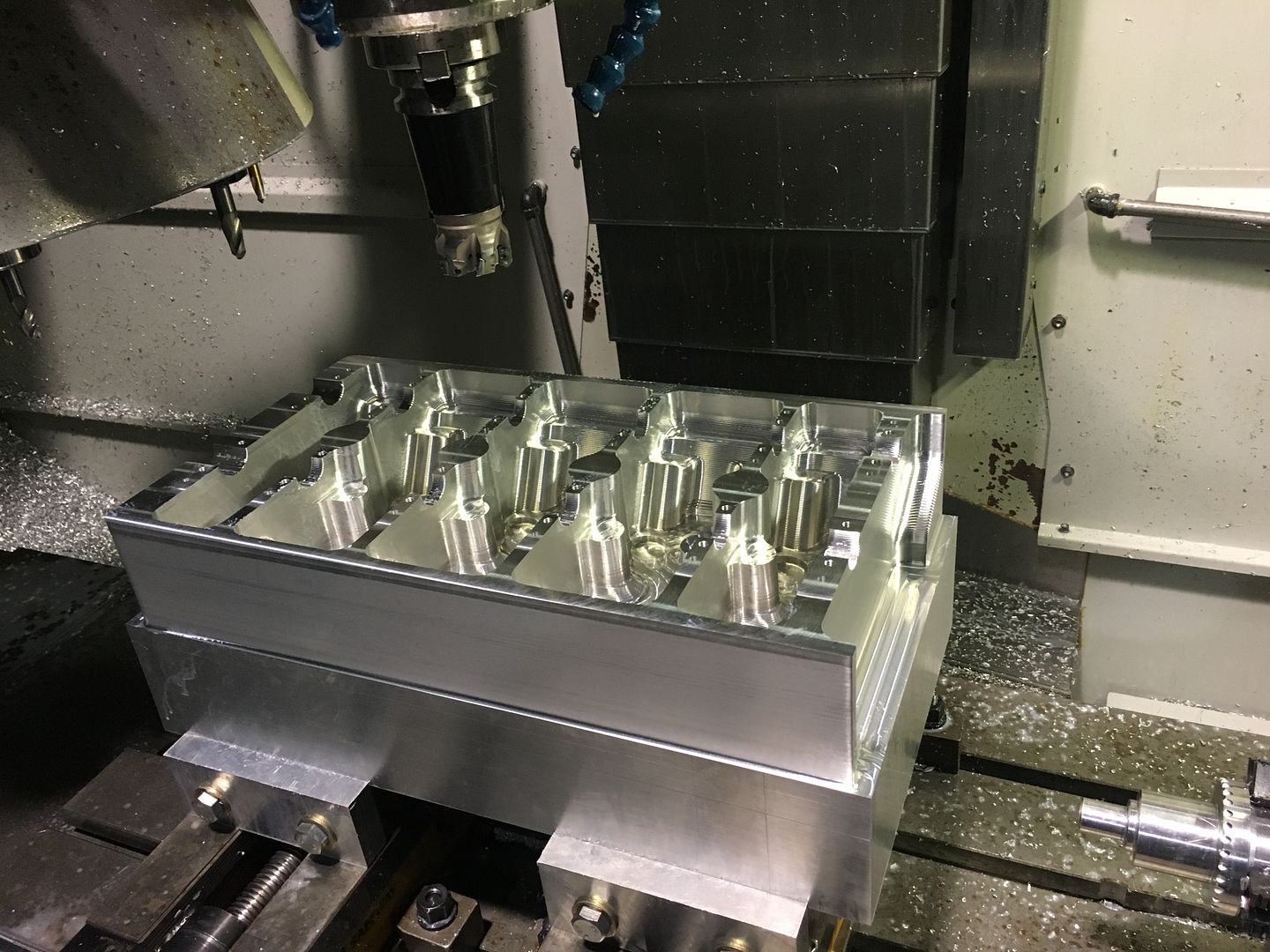

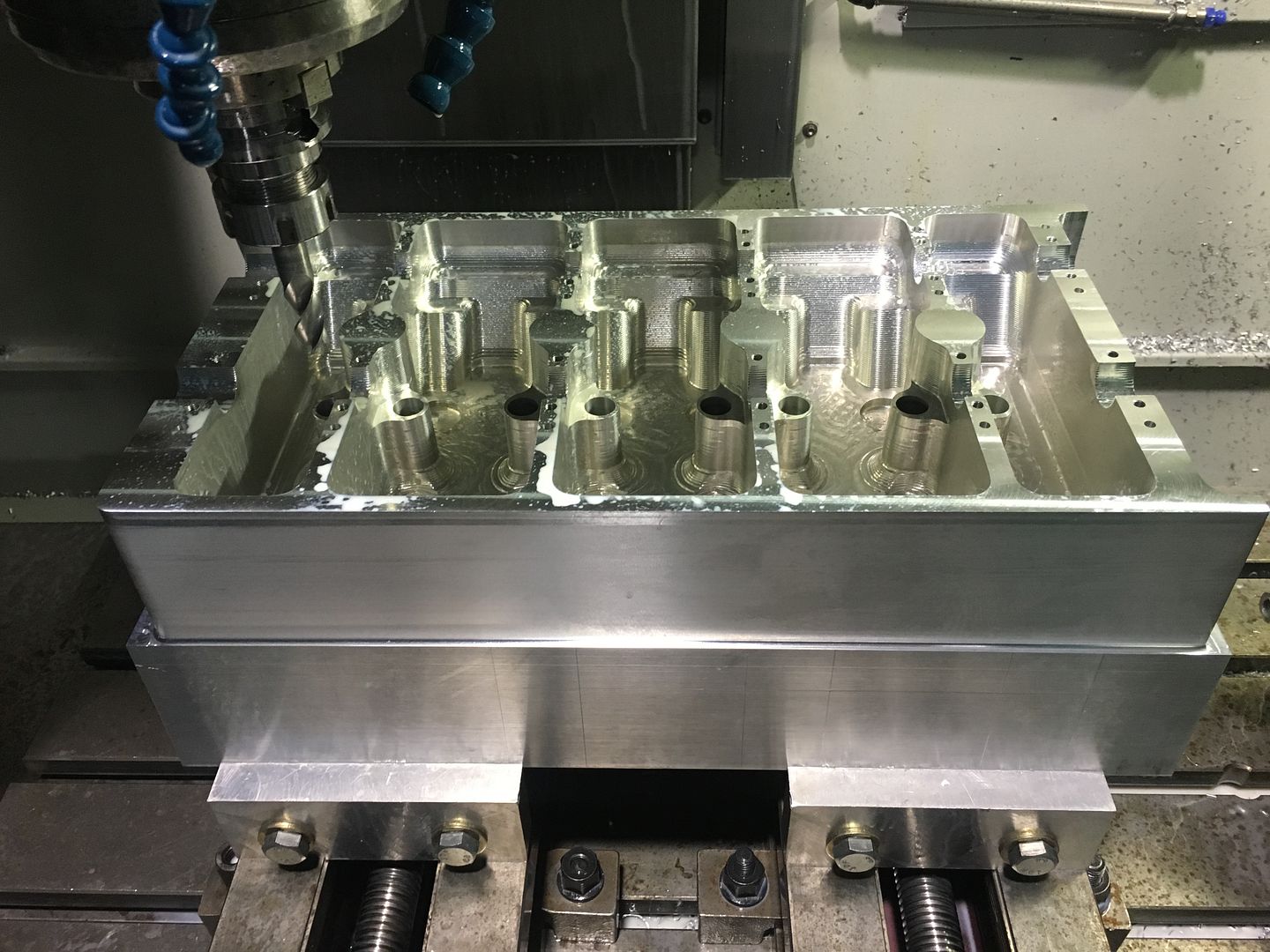

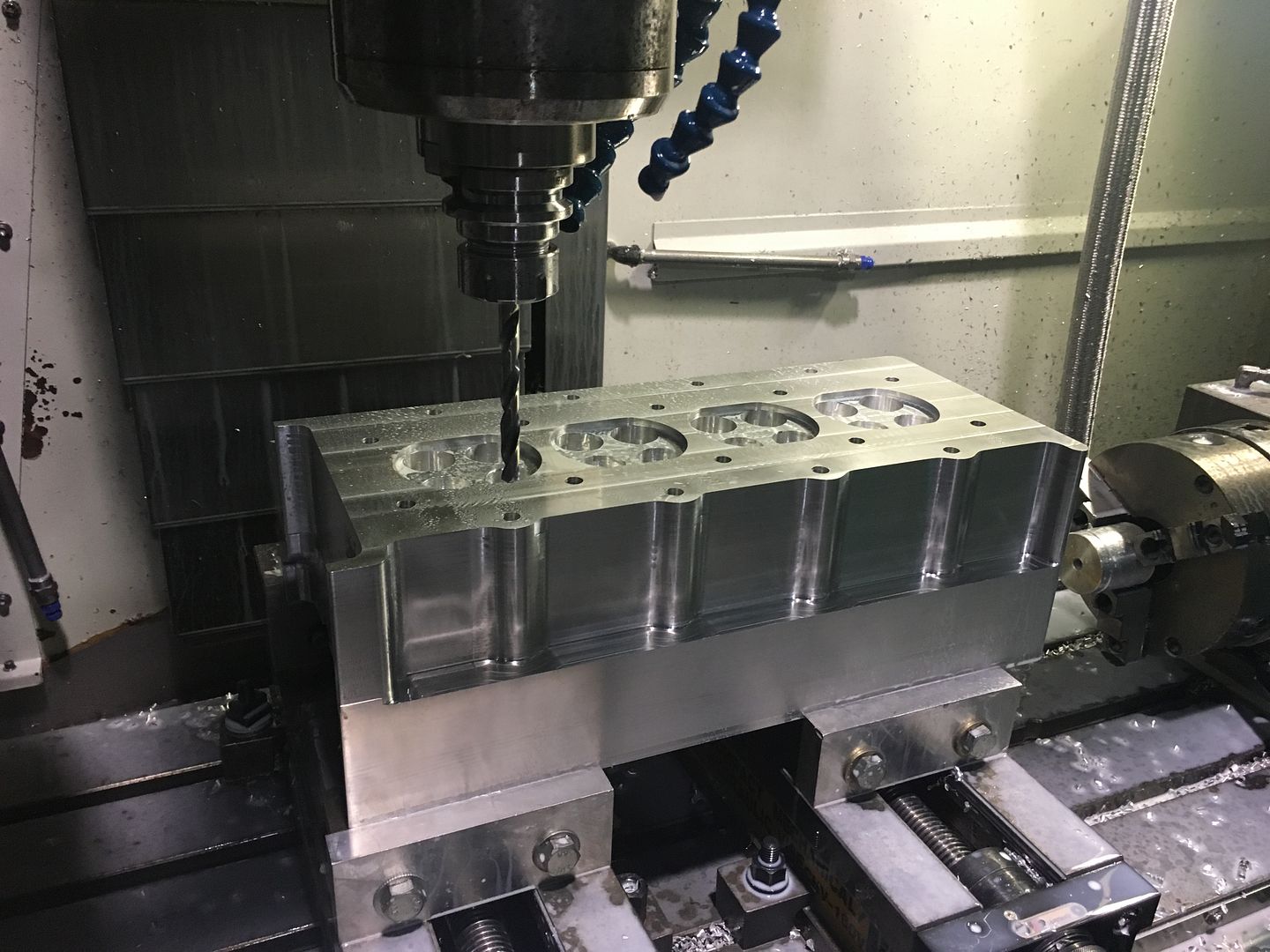

Whilst we are waiting on the parts to arrive from America the engine block, girdle and sump are well underway.

We have gone for a 6 bolt main design block instead of a factory 2 bolt main, with a full girdle assembly instead of individual caps, and a custom sump for the dry sump application.

Attached are some pictures of the block drawings and parts being machined

After setting his new class record in 2014, and finally getting into the 200mph club, suffering gearbox problems throughout the runs, 2014 was a great meeting for Mike, after returning home the gearbox was removed and inspected, completely rebuilt with an added paddle shift system, to help improve shift times, eliminate miss shifts, and keep the car stable throughout the run.

After setting his new class record in 2014, and finally getting into the 200mph club, suffering gearbox problems throughout the runs, 2014 was a great meeting for Mike, after returning home the gearbox was removed and inspected, completely rebuilt with an added paddle shift system, to help improve shift times, eliminate miss shifts, and keep the car stable throughout the run.2015 speedweek unfortunately didn't go to plan as we would have liked, onboard data showed Mike was travelling 45mph faster at the 1st mile mark than previously in 2014, before the engine decided it didn't want to play the game anymore.

After heading back home whilst the team felt heart broken we were still happy with the progress and the improvement on the car, after removing and inspecting the engine and several months talking, weighing up the pros and cons with what to do with the engine we have decided to get the modular 5.4 moving forward with a new engine program.

Several phone calls and emails to MMR in the states, discussing our best option, we all know building a drag engine is completely different to building an engine for salt lake racing Mike has decided let's push the 5.4 litre v8 to a whole new level, however we are up against a few challenges with the design of the factory engine to with stand the abuse and tortue a salt car engine gets put through.

Sure we can just grout fill the entire block and heads, use aluminum conrods and run methanol, but it's a salt car not a 6 second drag car.

So after many months of drawings, designs, calculations, costings, and sourcing parts we are finally well underway in the engine program to get the Mastec Ute back out on the salt. MMR are supplying a billet crankshaft, custom forged pistons, camshafts and a heap of other parts for the combination, however conrods are a weak point, we have organised a custom set of billet 300m conrods to be machined and all going into a custom billet engine block.

Whilst we are waiting on the parts to arrive from America the engine block, girdle and sump are well underway.

We have gone for a 6 bolt main design block instead of a factory 2 bolt main, with a full girdle assembly instead of individual caps, and a custom sump for the dry sump application.

Attached are some pictures of the block drawings and parts being machined